1/21 - 1/24

- Nathan Matarazzo

- Jan 23, 2025

- 2 min read

Updated: Jan 24, 2025

This week was cut short due to a few reasons. Firstly, on Monday, there was no school, since it was Martin Luther King Jr. day. Then, on Tuesday, I was only in shop for one period, since I had a field trip for mock trial later that day. Although, despite my circumstances, I was able to get a lot done in my short time in the shop this week. The first thing I had to do was determine which buttons I needed to order replacements for. I knew that I definitely needed one 5v red button, since that one was definitely broken. However, there was also a blue button in which the LED wasn't turning on. I messed around with this button on Tuesday, and I was able to determine that it, in fact, wasn't broken, but the connection was just a little messed up. So, I fixed the blue button, and on Wednesday I ordered a replacement 5v red button to replace the broken one. It should be arriving in a week or 2, and in the mean time, I am thinking of starting a new project to keep me busy. Oftentimes this week, I was doing research on what I might make next, so I will hopefully come to that conclusion over the weekend, and have a new project idea to start on next week while I wait for the button to come in.

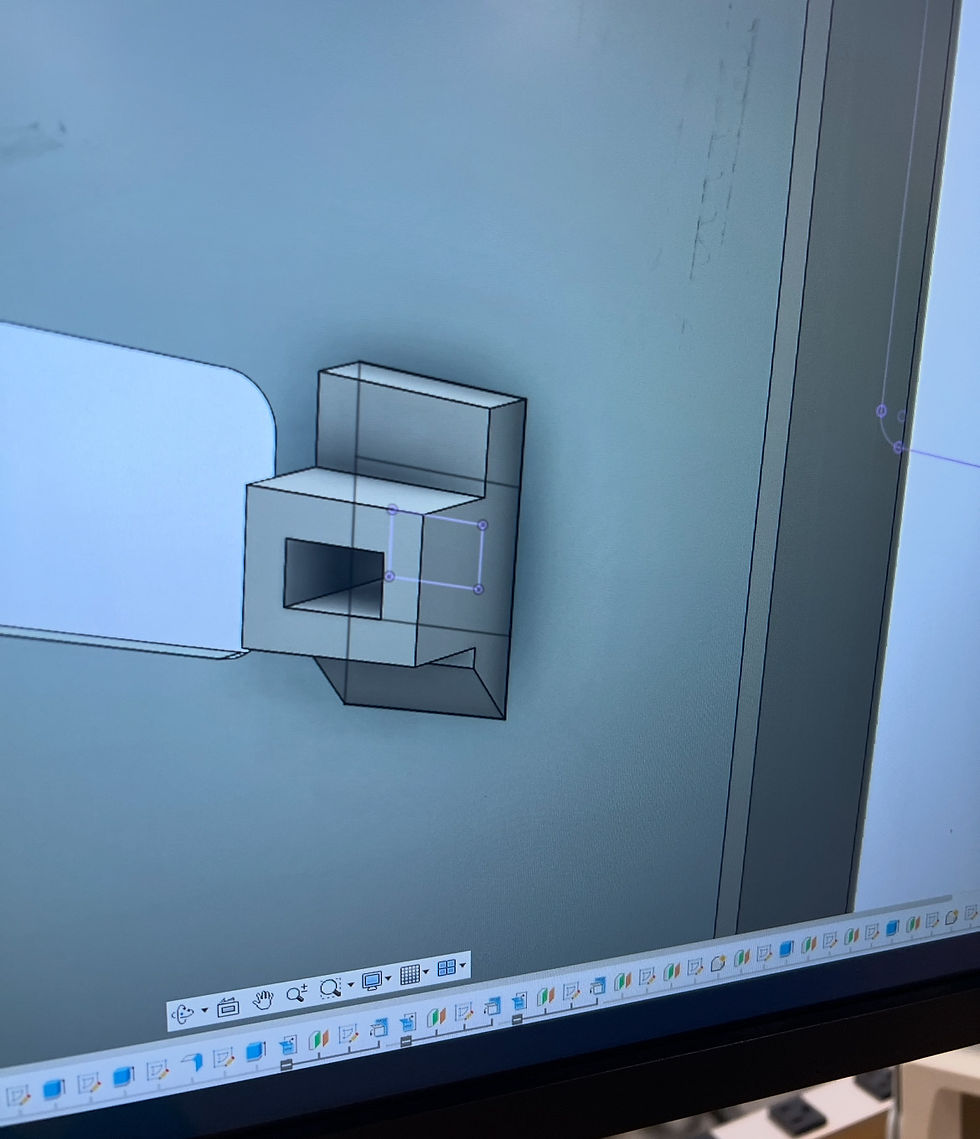

The next thing I did this week was use the water-jet to cut out some new pieces for Mr. L, one of my shop teachers. I had cut out similar pieces for him last week, but he wanted me to cut out the no excess piece again, just in a different thickness of aluminum. Using the water-jet, with the help of Milo Austin, a classmate of mine, I was able to re-cut the pieces out of 1/8 inch thick aluminum. These pieces can be seen in the pictures below.

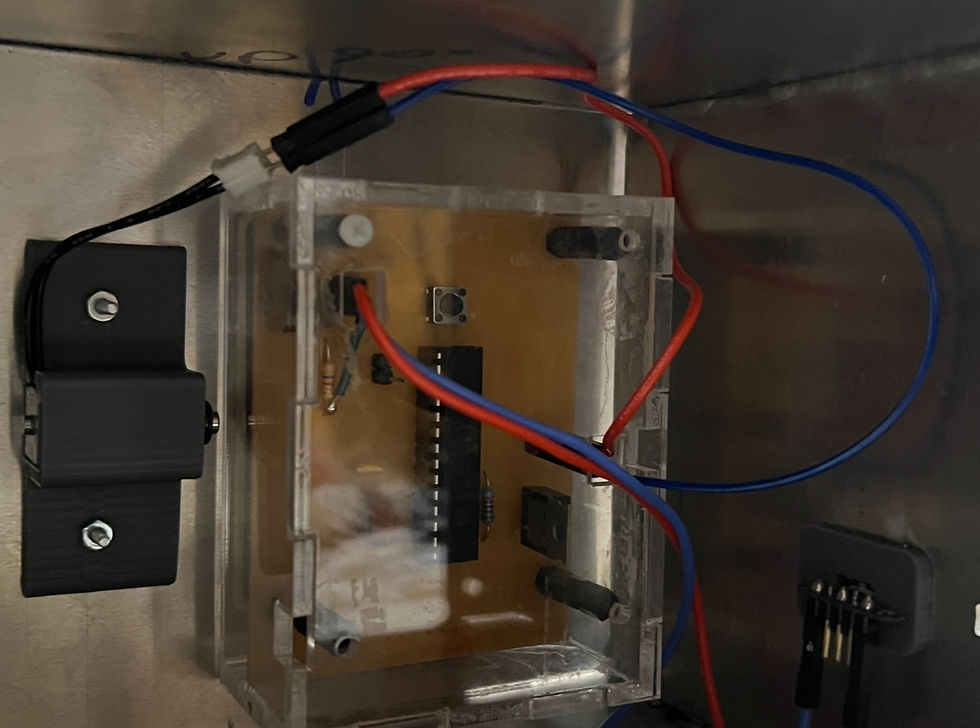

The final thing I accomplished this week was securing the PCB in my arcade machine design. First, I added standoffs to the PCB to keep the traces and solders from coming in contact with the table. I was concerned that the friction could cause some issues in the future, so I took these measures to remove that possibility. Next, I designed and laser-cut 2 bridge/holder pieces out of 1/4 inch wood. Finally, I used a hot glue gun to glue all the parts together, and the before and final results can be seen in the pictures below.

Comments