5/5 - 5/9

- Nathan Matarazzo

- May 9, 2025

- 2 min read

Updated: May 16, 2025

On Monday, I brought the sheet metal safe to metal fab to see if they could fold it. After a tumultuous process, they eventually told me that they couldn't fold it anymore and I would have to make a new one. Seen in the third picture below is what is left from the sheet metal safe after it had been folded many times and ripped apart by me. So, I had to make a new sheet metal design that would be folded and welded easier.

On Tuesday, I designed a new sheet metal design for the new safe I wanted to cut out. I worked really hard doing the CAD. Using the advice I received from Mr. Jackson, I made a new design. It is a really nice design, and I'm very proud of it.

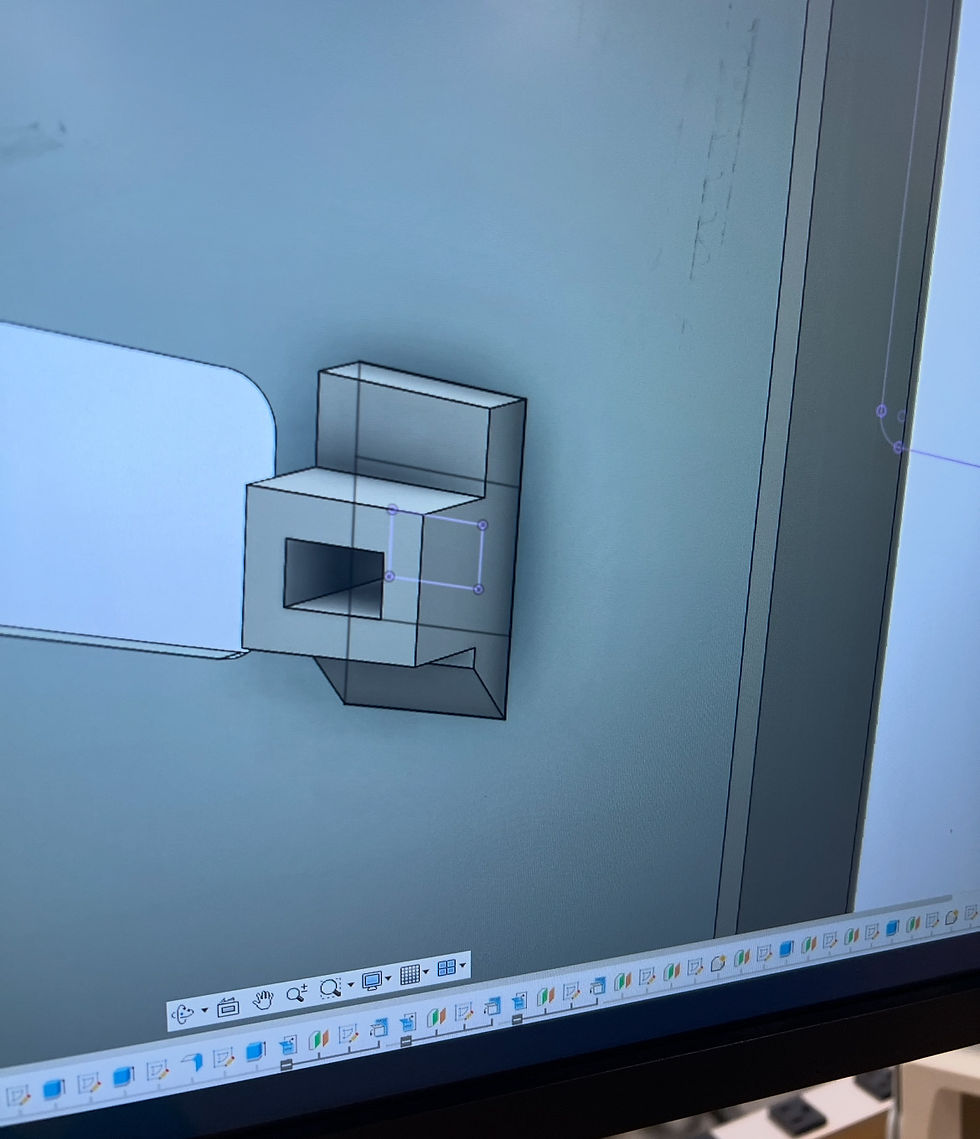

On Wednesday, I designed a new version of the USB Mount that will be more efficient, take less filament, and fit better into my safe. A photo of this design can be seen in the fourth picture below.

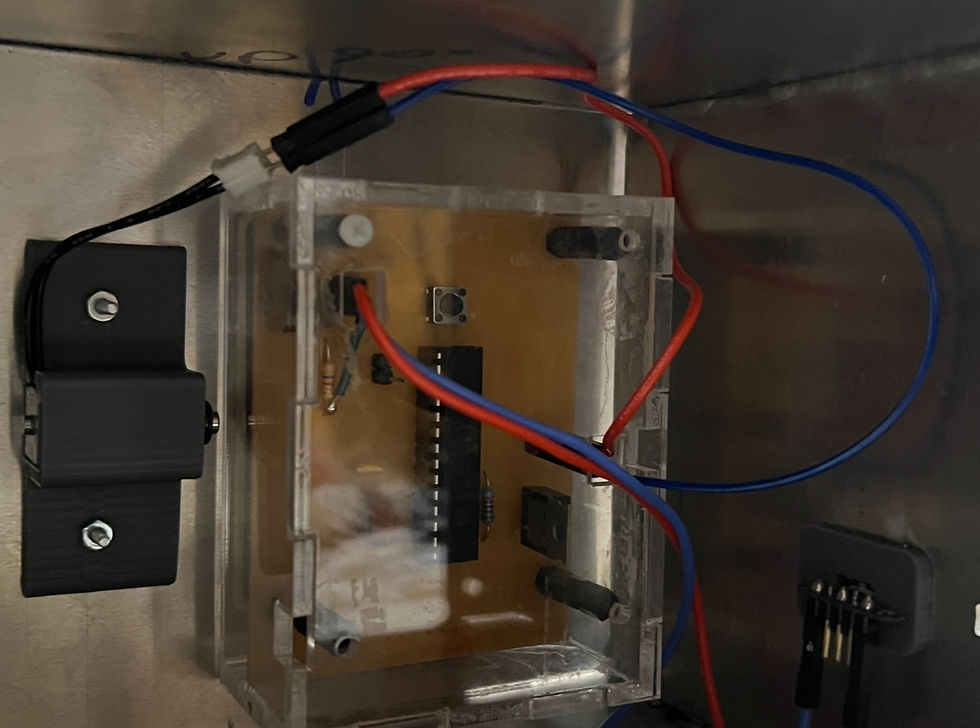

On Thursday, I started using the Waterjet to cut out the new pieces of the safe. Through my hard work and dedication, I was able to successfully cut everything out in only one day. The first picture below shows the pieces that had been cut out.

On Thursday night, we had the Medford Vocational Technical High School banquet. In the last image below, this can be seen. The banquet was this cool little event for the graduating Vocational class. I attended with a bunch of other classmates from Robotics & Engineering and also some people from other shops as well.

Comments