1/6 - 1/10

- Nathan Matarazzo

- Jan 10, 2025

- 2 min read

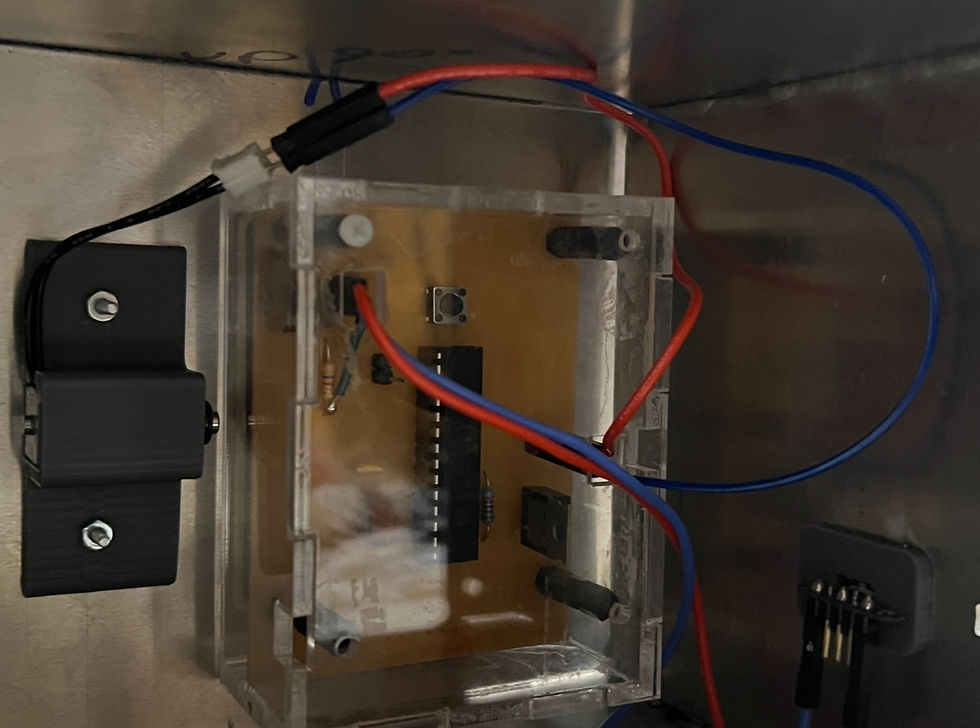

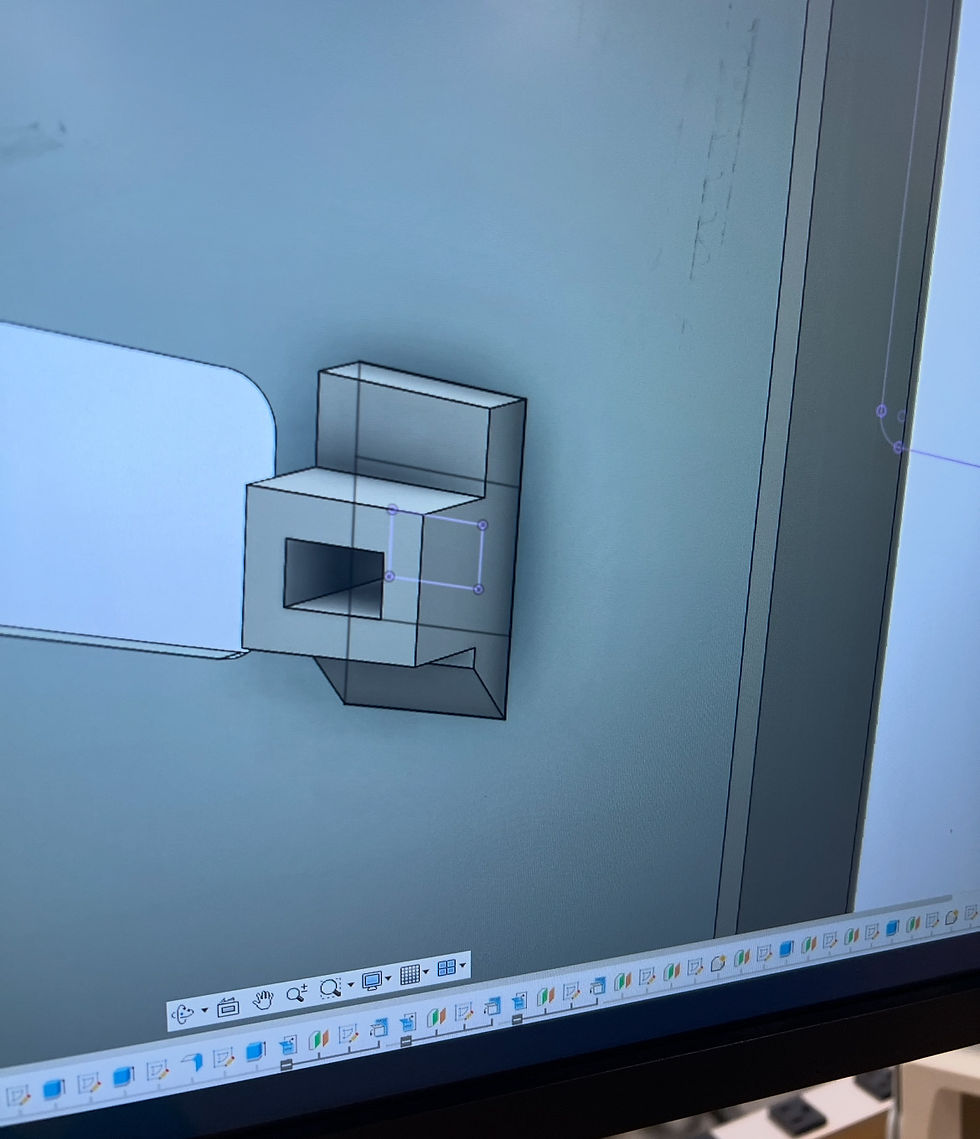

This week, I made a lot of progress toward finally being done with the arcade machine. Firstly, Mr.L, one of my shop teachers, asked me to use the water jet to cut out some pieces he was giving to a friend of his for his car. He wanted me to design the pieces in CAD first, but there was a lot of initial confusion as to what he wanted me to actually design. He said that he wanted one piece to have an offset and one piece to not have an offset. After careful pondering of what he meant by this, I finally understood it, and I designed these both in Fusion 360 over the course of a day. Then, I lasercut the initial design with the offset out of cardboard, and since there were no issues, I was ready to add those dxf's onto the water jet to laser cut. With the help of Sacha Silvia, a classmate of mine, I was able to learn the ropes of using the water jet and how to cut stuff out using it. As you can see in the picture below, I had to cut out 2 of each piece, making 4 in total. After I used the water jet to cut them out, I used another tool on the edges of the pieces to make them smooth. After this, I gave them back to Mr. L and was done with that project. Then, I continued working on soldering extensions to some of the buttons for the arcade machine, so they will work better. I am doing this so I don't have to use jumper wires to connect the buttons to the PCB. This is more efficient monetarily, and also, since there are less connections, it also leads to a decreased input delay, I have found. In the second picture below, there is a picture of a button without any extension. So far, I have finished soldering 5 out of the 11 buttons in total, and I plan to hopefully finish by the end of next week.

Comments